AL4RPV-50R

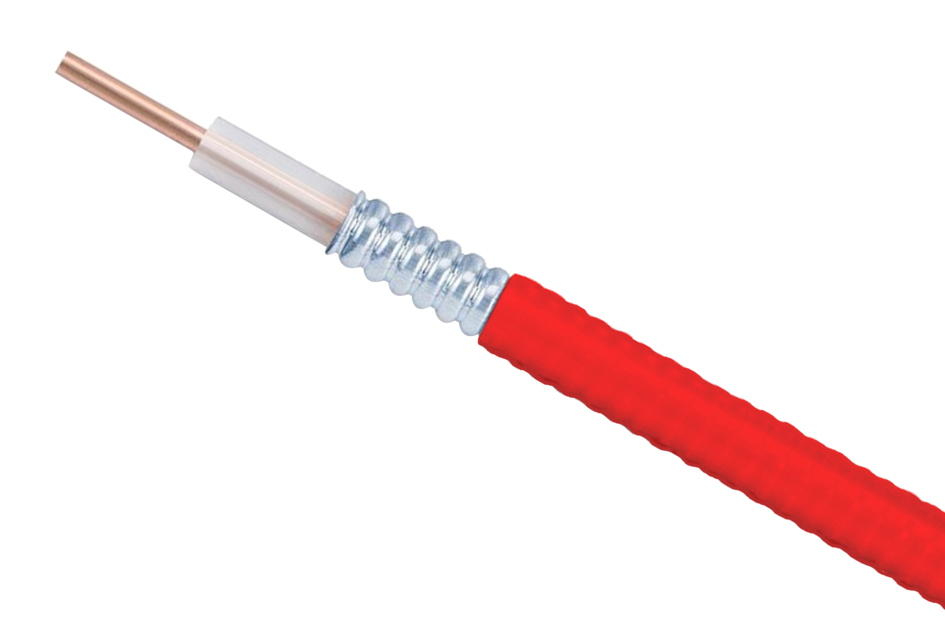

AL4RPV-50, HELIAX® Plenum Rated Air Dielectric Coaxial Cable, corrugated aluminum, 1/2 in, Red PVC jacket

Features and Benefits

- This product is part of the ANDREW Wired for Wireless® Solution

Specifications

Product Classification

| Product Type | Air coaxial cable |

| Product Brand | HELIAX® |

| Product Series | AL4-50 |

| Ordering Note | ANDREW® standard product (Global) |

General Specifications

| Product Number | 529299903/00 |

| Flexibility | Standard |

| Jacket Color | Red |

| Performance Note | Attenuation values typical, guaranteed within 5% |

Dimensions

| Diameter Over Jacket | 15.748 mm | 0.62 in |

| Inner Conductor OD | 4.572 mm | 0.18 in |

| Outer Conductor OD | 14.046 mm | 0.553 in |

| Nominal Size | 1/2 in |

Electrical Specifications

| Cable Impedance | 50 ohm ±2 ohm |

| Capacitance | 75.459 pF/m | 23 pF/ft |

| dc Resistance, Inner Conductor | 1.575 ohms/km | 0.48 ohms/kft |

| dc Resistance, Outer Conductor | 1.575 ohms/km | 0.48 ohms/kft |

| dc Test Voltage | 4000 V |

| Inductance | 0.19 µH/m | 0.058 µH/ft |

| Insulation Resistance | 100000 MOhms-km |

| Jacket Spark Test Voltage (rms) | 5000 V |

| Operating Frequency Band | 1 – 6000 MHz |

| Peak Power | 40 kW |

| Power Attenuation | 2.325000047683716 |

| Pulse Reflection | 0.5% |

| Velocity | 88 % |

Attenuation

Attenuation

| Frequency | Attenuation (dB/100 m) | Attenuation (dB/100 ft) | Average Power (kW) |

| 1.0 MHz | 0.216 | 0.066 | 35.37 |

| 1.5 MHz | 0.264 | 0.081 | 28.84 |

| 2.0 MHz | 0.306 | 0.093 | 24.95 |

| 10.0 MHz | 0.691 | 0.211 | 11.04 |

| 20.0 MHz | 0.985 | 0.300 | 7.75 |

| 30.0 MHz | 1.213 | 0.370 | 6.29 |

| 50.0 MHz | 1.581 | 0.482 | 4.83 |

| 85.0 MHz | 2.087 | 0.636 | 3.66 |

| 88.0 MHz | 2.126 | 0.648 | 3.59 |

| 100.0 MHz | 2.274 | 0.693 | 3.35 |

| 108.0 MHz | 2.368 | 0.722 | 3.22 |

| 150.0 MHz | 2.821 | 0.860 | 2.70 |

| 174.0 MHz | 3.054 | 0.931 | 2.50 |

| 200.0 MHz | 3.292 | 1.003 | 2.32 |

| 204.0 MHz | 3.327 | 1.014 | 2.29 |

| 300.0 MHz | 4.104 | 1.251 | 1.86 |

| 400.0 MHz | 4.808 | 1.465 | 1.59 |

| 450.0 MHz | 5.134 | 1.565 | 1.49 |

| 460.0 MHz | 5.197 | 1.584 | 1.47 |

| 500.0 MHz | 5.445 | 1.659 | 1.40 |

| 512.0 MHz | 5.517 | 1.682 | 1.38 |

| 600.0 MHz | 6.032 | 1.839 | 1.26 |

| 700.0 MHz | 6.583 | 2.007 | 1.16 |

| 800.0 MHz | 7.105 | 2.166 | 1.07 |

| 824.0 MHz | 7.227 | 2.203 | 1.06 |

| 894.0 MHz | 7.574 | 2.308 | 1.01 |

| 960.0 MHz | 7.892 | 2.405 | 0.97 |

| 1000.0 MHz | 8.081 | 2.463 | 0.94 |

| 1218.0 MHz | 9.068 | 2.764 | 0.84 |

| 1250.0 MHz | 9.207 | 2.806 | 0.83 |

| 1500.0 MHz | 10.256 | 3.126 | 0.74 |

| 1700.0 MHz | 11.053 | 3.369 | 0.69 |

| 1794.0 MHz | 11.416 | 3.480 | 0.67 |

| 1800.0 MHz | 11.439 | 3.487 | 0.67 |

| 2000.0 MHz | 12.192 | 3.716 | 0.63 |

| 2100.0 MHz | 12.559 | 3.828 | 0.61 |

| 2200.0 MHz | 12.920 | 3.938 | 0.59 |

| 2300.0 MHz | 13.276 | 4.046 | 0.57 |

| 2500.0 MHz | 13.975 | 4.259 | 0.55 |

| 2700.0 MHz | 14.656 | 4.467 | 0.52 |

| 3000.0 MHz | 15.649 | 4.770 | 0.49 |

| 3400.0 MHz | 16.928 | 5.159 | 0.45 |

| 3600.0 MHz | 17.551 | 5.349 | 0.43 |

| 3700.0 MHz | 17.859 | 5.443 | 0.43 |

| 3800.0 MHz | 18.164 | 5.536 | 0.42 |

| 3900.0 MHz | 18.467 | 5.628 | 0.41 |

| 4000.0 MHz | 18.768 | 5.720 | 0.41 |

| 4100.0 MHz | 19.066 | 5.811 | 0.40 |

| 4200.0 MHz | 19.363 | 5.902 | 0.39 |

| 4300.0 MHz | 19.658 | 5.991 | 0.39 |

| 4400.0 MHz | 19.951 | 6.081 | 0.38 |

| 4500.0 MHz | 20.241 | 6.169 | 0.38 |

| 4600.0 MHz | 20.531 | 6.257 | 0.37 |

| 4700.0 MHz | 20.818 | 6.345 | 0.37 |

| 4800.0 MHz | 21.104 | 6.432 | 0.36 |

| 4900.0 MHz | 21.388 | 6.519 | 0.36 |

| 5000.0 MHz | 21.671 | 6.605 | 0.35 |

| 6000.0 MHz | 24.420 | 7.443 | 0.31 |

Return Loss/VSWR

| Frequency Band | VSWR | Return Loss (dB) |

| 700–894 MHz | 1.130 | 24.30 |

| 806–960 MHz | 1.130 | 24.30 |

| 1700–2200 MHz | 1.130 | 24.30 |

Material Specifications

| Dielectric Material | PE spline |

| Jacket Material | PVC |

| Inner Conductor Material | Copper-clad aluminum wire |

| Outer Conductor Material | Corrugated aluminum |

Mechanical Specifications

| Minimum Bend Radius, multiple Bends | 127 mm | 5 in |

| Minimum Bend Radius, Single Bend | 63.5 mm | 2.5 in |

| Number of Bends, minimum | 15 |

| Tensile Strength | 79 kg | 174.165 lb |

| Bending Moment | 6.779 N-m | 5 ft lb |

| Flat Plate Crush Strength | 1.429 kg/mm | 80 lb/in |

Environmental Specifications

| Installation temperature | -5 °C to +60 °C (+23 °F to +140 °F) |

| Operating Temperature | -20 °C to +85 °C (-4 °F to +185 °F) |

| Storage Temperature | -20 °C to +85 °C (-4 °F to +185 °F) |

| Attenuation, Ambient Temperature | 20 °C | 68 °F |

| Average Power, Ambient Temperature | 40 °C | 104 °F |

| Average Power, Inner Conductor Temperature | 100 °C | 212 °F |

| Fire Retardancy Test Method | NFPA 262/CATVP/CMP |

Packaging and Weights

| Cable weight | 0.208 kg/m | 0.14 lb/ft |

Regulatory Compliance/Certifications

| Agency | Classification |

|

c(ETL)us Certification

|

CATVP/CMP |

|

ETL Certification

|

CATVP/CMP |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Product Classification

| Product Type | Air coaxial cable |

| Product Brand | HELIAX® |

| Product Series | AL4-50 |

| Ordering Note | ANDREW® standard product (Global) |

General Specifications

| Product Number | 529299903/00 |

| Flexibility | Standard |

| Jacket Color | Red |

| Performance Note | Attenuation values typical, guaranteed within 5% |

Dimensions

| Diameter Over Jacket | 15.748 mm | 0.62 in |

| Inner Conductor OD | 4.572 mm | 0.18 in |

| Outer Conductor OD | 14.046 mm | 0.553 in |

| Nominal Size | 1/2 in |

Electrical Specifications

| Cable Impedance | 50 ohm ±2 ohm |

| Capacitance | 75.459 pF/m | 23 pF/ft |

| dc Resistance, Inner Conductor | 1.575 ohms/km | 0.48 ohms/kft |

| dc Resistance, Outer Conductor | 1.575 ohms/km | 0.48 ohms/kft |

| dc Test Voltage | 4000 V |

| Inductance | 0.19 µH/m | 0.058 µH/ft |

| Insulation Resistance | 100000 MOhms-km |

| Jacket Spark Test Voltage (rms) | 5000 V |

| Operating Frequency Band | 1 – 6000 MHz |

| Peak Power | 40 kW |

| Power Attenuation | 2.325000047683716 |

| Pulse Reflection | 0.5% |

| Velocity | 88 % |

Attenuation

Attenuation

| Frequency | Attenuation (dB/100 m) | Attenuation (dB/100 ft) | Average Power (kW) |

| 1.0 MHz | 0.216 | 0.066 | 35.37 |

| 1.5 MHz | 0.264 | 0.081 | 28.84 |

| 2.0 MHz | 0.306 | 0.093 | 24.95 |

| 10.0 MHz | 0.691 | 0.211 | 11.04 |

| 20.0 MHz | 0.985 | 0.300 | 7.75 |

| 30.0 MHz | 1.213 | 0.370 | 6.29 |

| 50.0 MHz | 1.581 | 0.482 | 4.83 |

| 85.0 MHz | 2.087 | 0.636 | 3.66 |

| 88.0 MHz | 2.126 | 0.648 | 3.59 |

| 100.0 MHz | 2.274 | 0.693 | 3.35 |

| 108.0 MHz | 2.368 | 0.722 | 3.22 |

| 150.0 MHz | 2.821 | 0.860 | 2.70 |

| 174.0 MHz | 3.054 | 0.931 | 2.50 |

| 200.0 MHz | 3.292 | 1.003 | 2.32 |

| 204.0 MHz | 3.327 | 1.014 | 2.29 |

| 300.0 MHz | 4.104 | 1.251 | 1.86 |

| 400.0 MHz | 4.808 | 1.465 | 1.59 |

| 450.0 MHz | 5.134 | 1.565 | 1.49 |

| 460.0 MHz | 5.197 | 1.584 | 1.47 |

| 500.0 MHz | 5.445 | 1.659 | 1.40 |

| 512.0 MHz | 5.517 | 1.682 | 1.38 |

| 600.0 MHz | 6.032 | 1.839 | 1.26 |

| 700.0 MHz | 6.583 | 2.007 | 1.16 |

| 800.0 MHz | 7.105 | 2.166 | 1.07 |

| 824.0 MHz | 7.227 | 2.203 | 1.06 |

| 894.0 MHz | 7.574 | 2.308 | 1.01 |

| 960.0 MHz | 7.892 | 2.405 | 0.97 |

| 1000.0 MHz | 8.081 | 2.463 | 0.94 |

| 1218.0 MHz | 9.068 | 2.764 | 0.84 |

| 1250.0 MHz | 9.207 | 2.806 | 0.83 |

| 1500.0 MHz | 10.256 | 3.126 | 0.74 |

| 1700.0 MHz | 11.053 | 3.369 | 0.69 |

| 1794.0 MHz | 11.416 | 3.480 | 0.67 |

| 1800.0 MHz | 11.439 | 3.487 | 0.67 |

| 2000.0 MHz | 12.192 | 3.716 | 0.63 |

| 2100.0 MHz | 12.559 | 3.828 | 0.61 |

| 2200.0 MHz | 12.920 | 3.938 | 0.59 |

| 2300.0 MHz | 13.276 | 4.046 | 0.57 |

| 2500.0 MHz | 13.975 | 4.259 | 0.55 |

| 2700.0 MHz | 14.656 | 4.467 | 0.52 |

| 3000.0 MHz | 15.649 | 4.770 | 0.49 |

| 3400.0 MHz | 16.928 | 5.159 | 0.45 |

| 3600.0 MHz | 17.551 | 5.349 | 0.43 |

| 3700.0 MHz | 17.859 | 5.443 | 0.43 |

| 3800.0 MHz | 18.164 | 5.536 | 0.42 |

| 3900.0 MHz | 18.467 | 5.628 | 0.41 |

| 4000.0 MHz | 18.768 | 5.720 | 0.41 |

| 4100.0 MHz | 19.066 | 5.811 | 0.40 |

| 4200.0 MHz | 19.363 | 5.902 | 0.39 |

| 4300.0 MHz | 19.658 | 5.991 | 0.39 |

| 4400.0 MHz | 19.951 | 6.081 | 0.38 |

| 4500.0 MHz | 20.241 | 6.169 | 0.38 |

| 4600.0 MHz | 20.531 | 6.257 | 0.37 |

| 4700.0 MHz | 20.818 | 6.345 | 0.37 |

| 4800.0 MHz | 21.104 | 6.432 | 0.36 |

| 4900.0 MHz | 21.388 | 6.519 | 0.36 |

| 5000.0 MHz | 21.671 | 6.605 | 0.35 |

| 6000.0 MHz | 24.420 | 7.443 | 0.31 |

Return Loss/VSWR

| Frequency Band | VSWR | Return Loss (dB) |

| 700–894 MHz | 1.130 | 24.30 |

| 806–960 MHz | 1.130 | 24.30 |

| 1700–2200 MHz | 1.130 | 24.30 |

Material Specifications

| Dielectric Material | PE spline |

| Jacket Material | PVC |

| Inner Conductor Material | Copper-clad aluminum wire |

| Outer Conductor Material | Corrugated aluminum |

Mechanical Specifications

| Minimum Bend Radius, multiple Bends | 127 mm | 5 in |

| Minimum Bend Radius, Single Bend | 63.5 mm | 2.5 in |

| Number of Bends, minimum | 15 |

| Tensile Strength | 79 kg | 174.165 lb |

| Bending Moment | 6.779 N-m | 5 ft lb |

| Flat Plate Crush Strength | 1.429 kg/mm | 80 lb/in |

Environmental Specifications

| Installation temperature | -5 °C to +60 °C (+23 °F to +140 °F) |

| Operating Temperature | -20 °C to +85 °C (-4 °F to +185 °F) |

| Storage Temperature | -20 °C to +85 °C (-4 °F to +185 °F) |

| Attenuation, Ambient Temperature | 20 °C | 68 °F |

| Average Power, Ambient Temperature | 40 °C | 104 °F |

| Average Power, Inner Conductor Temperature | 100 °C | 212 °F |

| Fire Retardancy Test Method | NFPA 262/CATVP/CMP |

Packaging and Weights

| Cable weight | 0.208 kg/m | 0.14 lb/ft |

Regulatory Compliance/Certifications

| Agency | Classification |

|

c(ETL)us Certification

|

CATVP/CMP |

|

ETL Certification

|

CATVP/CMP |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Documentation & Downloads

Product Specification

Video

Positive Stop® Series Connectors Installation using a Manual Cable Preparaton Tool

Positive Stop® Series Connectors Installation using a Manual Cable Preparaton Tool

Positive Stop® Series Connectors Installation using an Automated Cable Preparaton Tool

Product Compliance Documentation

Product Specification

Video

Positive Stop® Series Connectors Installation using a Manual Cable Preparaton Tool

Positive Stop® Series Connectors Installation using a Manual Cable Preparaton Tool

Positive Stop® Series Connectors Installation using an Automated Cable Preparaton Tool

Other Ways to Browse