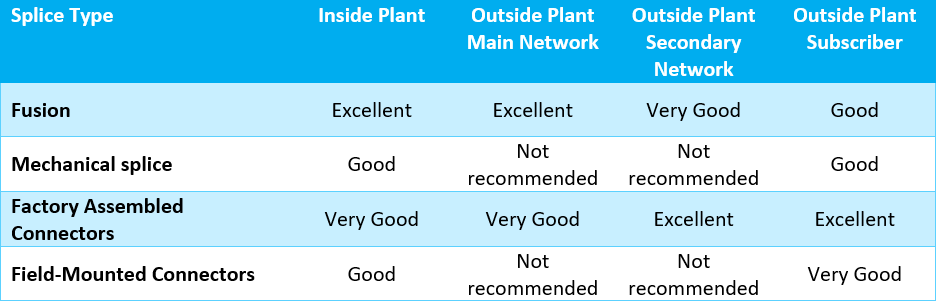

The fiber-to-the-home (FTTH) industry has grown exponentially in recent years. This has led to changes in the ways that networks are being deployed, and the methods used to patch fiber optic cables. In the past, patch alternatives were limited and expensive. They were mechanical splices, and splice by fusion or the use of connectors, which, due to their sensitivity, were generally limited to areas with a controlled environment. Technological evolution now enables successful fiber connections using any of these methods, in most environments. However, there are still differences between the different methods, which make it important to choose the right method for each case.

Here, we analyze each of these methods and when they can be most successful:

Fusion Splice

Fusion splicing is the most reliable method and offers the lowest optical loss. From a reliability point of view, fusion splices with a heat shrink splice protector are considered the most reliable. The cost of fusion machines has fallen, and their availability has increased. This method requires a relatively high level of preparation from the installer, when compared to other methods, however, modern splicers make the job much easier.

Mechanical Splice

Mechanical splice connections are less reliable and have higher losses than fusion splice methods. Some operators have concerns with the gel used to achieve inter-fiber coupling when using such mechanical splices in outside plant applications. There is also no method to indicate that the splice is done correctly (whereas there is a visual indication for fusion splicing machines by checking the splice on the screen). These mechanical splices are relatively easy to install, and do not require expensive equipment like splicers.

Connectors

Factory-Assembled Connectors

Factory-assembled connectors work great as long as proper procedures are followed and quality materials are used. If the standards regarding surface geometry are followed, IEC 61755-3, ferrules of stable material are used (preferably zirconium material) in protective housings, they remain stable when ferruled with surfaces adequately clean (and make good physical contact between fibers). Various grades of attenuation are available such as grade B (0.25 dB) and grade C (0.5 dB) according to IEC 61755-1. To ensure the proper functioning of these connectors, it is important to use cables with adequate features, such as jackets with low shrinkage, adequate movement of the buffers, and little growth of the fiber. Many cables exhibit an irreversible shrinkage phenomenon of the cable jacket or cable buffer tubes, which causes buckling of the fiber within the cable and connector. At low temperatures, optical losses can increase exponentially from these cable effects. MPO connectors are extremely sensitive to dirt. The entire surface of the ferrule must be inspected for debris, otherwise physical fiber-to-fiber contact will not be achieved. These factory-assembled connectors guarantee the level of losses, which is why they are usually more expensive than field-assembled connectors.

Field-Mounted Connectors

Field-installable connectors in their mechanical and fusion splice versions have higher losses than factory-installed connectors. There is no good indication that the connector is properly installed. This makes the modal power interference (MPI) issue important, as having two or more fiber connections within a short distance of each other can result in severe wavelength-dependent attenuation if one of the connections shows a huge loss. Reliability in outside plant is highly dependent on cable characteristics (such as permanent cable jacket shrinkage, buffer movement, and fiber growth). These connectors can be the most cost effective, however, care must be taken where and how they are used so the integrity of the network is not jeopardized.

Where should we use each type of splice?

Determining the most appropriate type of splice depends on many parameters. For example, where greater network reliability is required, fusion splicing is the best option. Mechanical splicing is a good alternative for cable repair, however, depending on the quality, it can be affected over time, especially in external environments. Factory-assembled connectors are the best option for cables used in the outside plant, where reliable connections need to be guaranteed. The use of hardened factory-mounted connectors has grown in recent years because they allow faster installation and come with a manufacturer's leak-proof guarantee. Field-mounted connectors are an inexpensive and quick-to-install alternative, provided there is no risk to the network.

When looking at the overall options, the fusion splice is undoubtedly the best in terms of quality and reliability. Cables with factory-assembled connectors are a very interesting alternative, since, even though they do not reach the same levels of loss as a fusion, they allow fibers to be patched quickly and with adequate performance. Field-mounted connectors could also be used, , but given the number of factors that can affect the quality of these, it is important to limit their use to where possible failures do not affect network performance. Finally, mechanical splices are a good alternative for quick repairs, but long-term reliability makes them less suitable for outside plant uses.

The choice is not easy, especially when it comes to balancing cost, quality, speed of deployment, and long-term performance. Whatever the selected solution, it is important to ensure that they are made with top quality materials, extensively tested, and with a guarantee, otherwise the quality and longevity of the networks can be put at risk. At CommScope, we spend a lot of time defining the best materials for each application to ensure we offer quality products that enable your company to deploy networks capable of supporting the services of today and the future.