“To clean or not to clean, that is the question.” I might not have quoted Hamlet exactly right. Nonetheless, that question is exactly what cell site technicians have to answer during every fiber cable and connector installation. Keeping the connector clean is of utmost importance to network performance.

“To clean or not to clean, that is the question.” I might not have quoted Hamlet exactly right. Nonetheless, that question is exactly what cell site technicians have to answer during every fiber cable and connector installation. Keeping the connector clean is of utmost importance to network performance. The design and production of today’s fiber connectors have eliminated most of the difficulties in achieving core alignment and physical contact when installed. The challenge that remains is maintaining a pristine end-face. As a result, contamination is the number one troubleshooting problem for optical networks. Abrasive particles (namely, rock dust) can cause permanent damage to the interface. If an interface is scratched, it cannot be repaired. It has to be replaced.

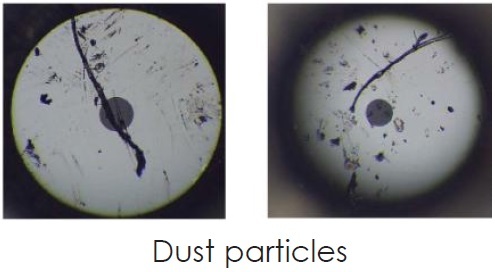

The problem in trying to maintain a pristine connector interface is that dirt is everywhere—you just can’t see it. It is airborne, on your hands and clothing, in bulkhead adapters and test equipment, and anywhere else you can imagine. The average dust particle is not visible to the human eye. But a single speck of dust can be a major problem when embedded on or near the fiber core. Dust caps protect the fiber end-face, but can also be a source of contamination if re-used. Test gear interfaces are typically the major source of contamination because of the repeatable use.

Implementing a process of cleaning and inspecting fiber connectors before mating can reduce the time spent troubleshooting, optimize signal performance, and prevent damage. The process we suggest is:

- clean with a cleaning tool,

- inspect with a microscope,

- clean again if required,

- inspect, then

- install when it’s clean.

For a visual demonstration, check out this one-minute video of the cleaning and scoping for Dual LC connectors. You can also review our Cleaning and Inspecting Bulletin for more details.

So the answer to the question, “to clean or not to clean” is pretty simple. Clean…and clean again if needed. You can’t see the dirt, but it could be there. Make sure your fiber connections are pristine by keeping them immaculate.